Founded in 1976, Cooling Tower Maintenance Inc. (CTM) is the largest and oldest independent maintenance and service company for cooling towers in Canada. With over thirty employees between two sites, this generational business is critical for climate control in buildings such as hospitals, care homes and industrial settings. Because of this, the company is considered an essential service provider which allowed it to work through the Covid-19 pandemic and emerge without any major damage done, though not completely unscathed.

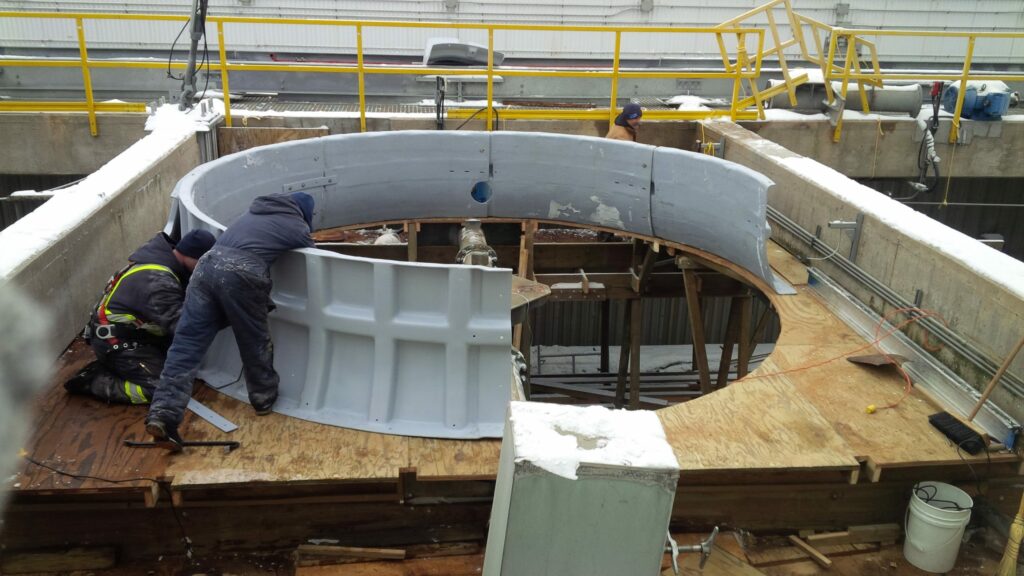

Cooling Towers essentially act as giant radiators which provide cold water for air conditioning units on a large scale. Cooling Tower Maintenance does exactly what the name says – it services, repairs, and replaces cooling towers, while also humidification solutions and air conditioning units for lease and sale. With roots dating back to the 1950s, CTM has always had a ‘people-focused’ approach to business. Asked what the secret to longevity was, General Manager of CTM, Mitchell Cross, had no hesitation in responding with one word that said it all – “people.” Explaining further, Mitchell went on to say that a “stable” ownership group, along with the people you employ, are essential.

According to Mitchell, family businesses offer a generational approach, whereas other companies may look to be bought out when they reach a certain size, losing that relationship they had established between the company and the client – “without a generational approach, ownership sells, and people move on.” When a business adopts a generational approach, it builds a relationship between the company and the client, a relationship that proves to be essential to the business’s reputation. Mitchell explained to me that “being out there on a regular basis has helped to create a brand awareness,” with CTM receiving parts requests from across Canada. Quality of service at a fair price is extremely important to CTM, providing clients with options that best suit their needs and their budget. Such as repairing or rebuilding tower rather than replacing it can save thousands of dollars. Also, the option of top quality parts, but not at the OEM price. And regular servicing and maintenance contracts to help prevent unnecessary repairs.

CTM were deemed an essential service through the Covid-19 Pandemic – machinery continues to break down regardless of what is going on in the world, and service companies need to be on hand to fix them. If anything, due to decreased numbers of employees working in the offices as they were mostly working from home, more work ended up being done as opposed to less. CTM’s work, according to Account Manager Patrick Sweeney, is loud, intrusive, and disruptive, as the site needs to be shut down for them to undergo their work. Alongside this, the cooling towers are positioned outside, with employees working in crews of two, meaning social distancing was not a major concern as CTM provided all the PPE required. Throughout the pandemic, CTM were able to overcome issues arising as a direct result of restrictions put in place and fulfil their obligations to their customers.

“Being out there on a regular basis has helped to create a brand awareness, with CTM receiving parts requests from across Canada.”

One major aspect that was a true casualty of the pandemic for CTM was labour shortages. With many people being offered sixty per cent of their usual wage for staying home throughout the pandemic, it has led to fewer skilled professionals being willing to work in the same way they had in previous years. CTM found that to attain skilled professionals to employ, they are continuing to have to offer a higher wage, oftentimes for less skill – raising the prices of those higher up in the field, rightfully so – but this acts as a cycle that may prove difficult to break for companies. This, along with the cost of materials rising exponentially, raises the question for Patrick – is “stagflation” making a comeback? With service and maintenance roles, you must do a lot of hard work all year round, and both Patrick and Mitchell expressed their opinions that currently there is more incentive for skilled professionals to stay at home, as opposed to working in all types of conditions all year – with most (65-75%) of CTM’s work carried out mainly in the months of September to June, as Air Conditioning cannot be worked on while it is being used in the summer months.

CTM have established a great reputation for themselves in the HVAC industry in Canada since their establishment; they have been regular attendees of the Trade Show for almost fifteen years, where they would connect with potential customers and other companies – though in the last six years, for CTM the trade show has become more of a way to remind people that CTM is still there and pushing new products that they are releasing. Throughout the pandemic, Patrick explained how “B2B (business to business) has become a major casualty” as now, most of the sales he completes are through email. The previous, direct interpersonal method of selling is a thing of the past, and has been replaced by online orders and video conferencing. This is proving to be more cost-effective and time-efficient for the company as it eliminates increased travel costs and better time management. As Patrick put it “If you’re not focusing on the online stuff now, you’re so far behind.” Both Patrick and Mitchell explain to me how most of their “marketing and advertising has been pushed to an online presence now,” as is the case with many other businesses – moving to an online presence had been happening previously, but Covid has accelerated the change. By way of explanation, Mitchell explained to me how previously he would travel to CTM’s office in Calgary every nine weeks for two or three days, whereas now only travels out twice a year because is everything is changing and moving to a virtual presence.

Beyond towers, CTM has seem significant growth in the Humidification Division since the pandemic. They have carried a carbon-free and low energy line, the UltraSonic line for many years now, sold as a green energy product; but due to the results of recent studies, they have seen a tremendous uptick in the sales of these products. Studies showed that high levels of humidification in the ranges of forty-four to fifty-five per cent in winter pays a tremendous benefit to mitigate the transmissibility of viruses. Because of this, CTM’s UltraSonic line along with their electric humidification products has grown exponentially, due in part, according to Patrick, to “high profile companies wanting to show their staff their Covid preparedness.” When asked about what’s next for CTM, both Mitchell and Patrick explained that they have seen tremendous potential in the growth of Humidification and that they “understand it extremely well in a marketplace where most don’t,” as they not only sell it but take care of it long-term for the client. They plan to roll this out nationwide in due course. CTM are also planning to expand to an office in British Columbia within the next five years, which would allow them to reach other areas of Canada not covered by their current two offices. At this point in the business’ lifetime, it is more about protecting the brand than expanding it. They have already done a lot of the “start-up” work, such as speaking to businesses, and creating a universal presence – meaning now it’s all down to the people. Mitchell explained that when “opening an office in a new area, you have to have a local presence – you can’t run a business from another province and make it work properly – it’s all about hiring local sales staff and techs.” With all this in mind, it’s clear that CTM are facilitating the reopening of businesses following the Covid-19 Pandemic – with humidification being so important in mitigating the spread of Covid-19, CTM are making it easy for companies to adjust to the post-pandemic way of working.