MCON and its products are often the first part of a construction project, literally laying the foundation of a construction site. By building safe, healthy, and thriving cities through the projects it takes part in, the company echoes this work in a figurative sense, too. Think: the redevelopment of hospitals, the construction of new residential communities for people to live and raise families, the expansion of its own business to increase production and create more local jobs. This commitment to community has been a thread through M CON’s work since the very beginning.

M CON is deeply committed to people and innovation, producing a comprehensive range of high-quality products tailored to meet its customer’s needs. The company invests in highly skilled individuals who embrace challenges with creativity and a commitment to finding innovative solutions. Constantly improving its manufacturing processes, M CON ensures the timely delivery of competitively priced, high-quality products.

Located in Canada’s capital city of Ottawa, Ontario, M CON’s CPCQA certified production facility spans 10,291 square meters and is equipped with state-of-the-art manufacturing equipment. This facility includes ample heated indoor storage for raw materials and a computerized batching plant, ensuring consistent quality in its precast concrete products. Additionally, the site boasts over 161,874 square meters of storage for finished products, enabling customers to access a ready inventory to kickstart its projects efficiently.

Today, the company employs around 93 people, many of which have been part of the company since the 1990s.

“I think we’ve perfected our production process over the 35 years,” says Marco Mion, General Manager, of the company’s ability to weather challenges and remain successful year over year. “You know, we face the same challenges that everybody’s facing now, post-COVID. Things like employee retention, funding, shortage of labor and skilled machine operators,” he adds. It’s exactly these challenges that have forced the company to constantly innovate and adapt, looking internally at hiring practices or production processes and seeing where there might be an opportunity for improvement.

Over the years, M CON has shifted its operating approach. In an attempt to make jobs simpler and more efficient, it has incorporated more automation. The company purchased the latest tools and technology, streamlining many of its production processes. “Another step in the direction of seamless production involved revising the leadership structure for the unionized staff to create a supervisory level, which allowed us to empower these supervisors to make more decisions, but also create a more defined career path in our manufacturing facility positions, leading to stronger corporate culture and ultimately, better retention.”

“Another step in the direction of seamless production involved revising the leadership structure for the unionized staff to create a supervisory level, which allowed us to empower these supervisors to make more decisions, but also create a more defined career path in our manufacturing facility positions, leading to stronger corporate culture and ultimately, better retention.”

Early on in the pandemic, M CON saw a lot of its veteran employees, many of whom had been part of the team since the 1990s, take early retirement. This, understandably, left major gaps in the organization. Many of these individuals had worked for so long, the scope of their role had expanded so greatly with decades of expertise. Replacing them proved difficult. Often, two people were needed to fill the shoes of someone departing. M CON refocused efforts on recruiting talent, going into local colleges and universities including Carleton and Ottawa Universities, Algonquin College and St. Lawrence College as well local high schools to establish a presence at job fairs, and recruit students for summer co-op terms. A few years on, this has borne fruit with many meaningful hires taking place right after graduation.

M CON is also focusing on training and upskilling current employees. The company utilizes a variety of government grants intended to offset the cost for businesses so that it can invest in professional development for its skilled laborers. The goal is to keep pace with an ever-changing industry and continue delivering high-quality work on a variety of projects that benefit the health, wellbeing, and comfort of its community. These projects range from hospital redevelopments to residential housing builds and of course, investment through a plant expansion has been integral to the delivery of these.

In fact, in November 2023, M CON completed and commissioned another plant expansion aimed to enhance the production capabilities for custom wetcast concrete production. The project included expanding one of the original production bays by 555 square meters and moving two existing 20,000 kg cranes to this bay. This expansion’s primary focus is to increase production capabilities of the Stone Strong retaining wall blocks, 1200/1500 mm diameter pre-bench maintenance holes, 1500/1800 mm diameter monolithic maintenance holes, drop structures for 1200 mm diameter maintenance holes and 1200-1800 mm diameter oil-grit separator structures.

The recently completed (2022) expansion next to this production bay also received a lifting capacity upgrade to a total of 60,000 kg. This 1401 square meters production bay will be focused on producing large and heavy precast concrete box culverts, chambers, water retention systems and other custom solutions for the infrastructure market.

These two production bay expansions allow for the manufacturing of even larger and more complex precast concrete structures. The expansions involved additional capital investments that went towards new forms, increased production lines and the opportunity to apply new technologies to concrete manufacturing.

This state-of-the-art facility represents a commitment to quality, innovation, efficiency, and sustainability in the production of essential components for modern urban development, including state-of-the-art health care facilities and residential housing.

Some other project highlights include:

OTTAWA HOSPITAL CIVIC CAMPUS PARKING GARAGE RETAINING WALLS

The Ottawa Hospital’s Civic Campus redevelopment project includes the construction of a new parking garage with associated retaining walls. This initiative is part of a larger effort to develop a modern and expansive hospital campus. The garage will feature a rooftop park and a four-story structure that integrates with the main hospital building via a weather-protected highline pathway. This highline will connect various facilities, including meeting rooms, retail spaces, and a cafeteria. M CON is producing blocks for 11 walls, with a face of 2,971.5 m2.

“They are tall walls which require us to work with the consulting engineer to design them utilizing our new D-150 Stone Strong block, which allows walls to be higher with no tie backs,” says Marco of the challenges this project presented early on.

The project aims to enhance the hospital’s capacity to provide advanced medical services and support infrastructure. The hospital will include 641 inpatient beds, with nearly 100 dedicated to critical care, and will serve as one of the most advanced trauma centers in Eastern Ontario. The design also emphasizes sustainability and community well-being, incorporating green spaces and pedestrian-friendly pathways.

The planning process has involved significant community consultation, with feedback sessions held to address concerns and gather input from local residents and stakeholders. This engagement is critical for ensuring the project meets both the healthcare needs and the expectations of the community.

RICHMOND MEADOWS SUBDIVISION

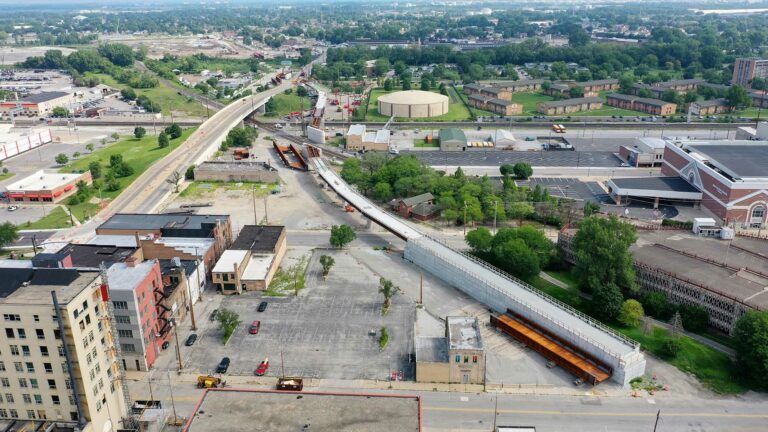

The Richmond Meadows Subdivision project is a significant new development designed to enhance community living in the region. This ambitious project faced a unique challenge when an elliptical pipe, specified for its underground infrastructure, was found to be available only in the United States. The tight project timeline meant that ordering from the U.S. posed logistical hurdles, as it would require 50 to 60 truckloads from Michigan, leading to potential delays and increased pollution due to long-distance transportation.

In response to these challenges, the developers collaborated with consultants M CON team, and the City of Ottawa to find a more sustainable solution. After extensive discussions and thorough reports, they succeeded in switching to a product that could be manufactured locally in Ottawa. This local 2400 x 1800 mm box culvert alternative not only adhered to the required specifications but also ensured a steady supply, as it could be produced at a rate of 10 to 12 pieces per day, with an additional casting to create a low flow channel.

This change resulted in significant savings for the developer and reduced the project’s environmental impact. By sourcing materials locally, the project minimized pollution associated with transportation and supported the local economy. Richmond Meadows Subdivision stands as a testament to effective problem-solving and sustainable development practices, setting a positive example for future projects.

As M CON embarks on its 35th year in business, the company is more committed than ever to sustainability and future growth. Over the past few years, M CON has taken significant steps to minimize waste in its production processes and supply usage. The implementation of a robust recycling program in both the office and the plant is regularly reviewed and improved each year, reflecting the company’s dedication to reducing its environmental footprint.

Looking ahead, M CON plans to adopt even more sustainable practices. This commitment is rooted in the belief that the company’s success is largely attributable to its dedicated team and loyal clients —many of whom have been with M CON since its inception. The trust and support from both employees and clients have been fundamental to the company’s growth and longevity.

In the next 35 years, M CON aims to continue its expansion, creating more jobs and enhancing the production team’s experience through facility improvements.

“Being responsible stewards to the community and continuously finding ways to improve as a company are top of mind,” says Marco. Whether through sustainable practices or refining production processes and quality, M CON is dedicated to evolving and becoming better each year.

“In the next 35 years we want to continue growing, while ensuring we make a positive impact on both the industry and the environment.”

Reach out to M CON today for a quote by visiting the website and filling out this form.