Bobby Unser, iconic American car racing champion, once said, “Success is where preparation meets opportunity.” This sentiment can easily be illustrated in a study of the remarkable evolution of StructureCast from a company focused on ready-mix concrete to a California-based powerhouse in the precast concrete space. StructureCast specializes in the production of custom architectural and structural precast concrete, serving the western US with project sites in California, Oregon, Washington, Nevada, Colorado and Arizona. Its product line spans both above ground and underground applications, with a focus on wall panels, building cladding, and architectural precast tailored for high-rise and multi-story buildings. Emphasizing structural integrity and load-bearing capacity, the company operates under a design-build model, combining manufacturing and contracting services. Distinguished by its California and Nevada contractors licenses, the company has the unique ability to function as both a manufacturer and contractor. This dual role allows it to undertake the entire process, from design and engineering, through manufacturing to delivery and installation. StructureCast is committed to delivering customized, high-quality precast concrete solutions for diverse construction projects.

Under the leadership of Brent and Anna Dezember, the company has always prioritized being at the leading edge of the industry to be prepared for whatever opportunities arise. The husband-and-wife team founded Golden Empire Concrete in the early 1980s. This ready-mix company maintained a non-union structure in a growing market making it a target firm, attractive for acquisition. Although the Dezembers weren’t listing Golden Empire Concrete for sale, when the opportunity arose, they decided it was an offer they couldn’t refuse. This opened the door to launch a new endeavor and take advantage of the prospect of creating new success in a different stream of the concrete market. They seized the opportunity and purchased a small precast company with an inventory of forms which manufactured utility products such as septic tanks and stormwater management structures. Just as with the ready-mix concrete market, Brent and Anna found success in the precast industry. Seizing the opportunity, they took advantage of their foothold in the industry, reimaged the company’s structure and deliverables and diversified the company’s into four product lines: architectural cladding, underground utility structures, precast fencing systems, and sustainable prefab modular buildings. StructureCast was born.

Today, StructureCast is a booming precast concrete heavyweight dominating the market with a workforce of 85, a strong leadership team of 15, and in-house engineering capabilities; something that can be hard to find. “Having our own experienced engineering team is really a competitive advantage,” says Anna Dezember. “This helps us maintain a high degree of control in our projects and offer value-added, design-build experience to our customers.”

The other distinctive asset that is a source of pride for the team at StructureCast are the qualifications and certifications of members at every tier of the organization. “We are committed here at StructureCast to qualification and certification at the highest levels, from our engineers and project managers to our production team and quality control laboratory,” says Anna. “This is very important in our industry. This sets us apart from many of our competitors. We work hard to achieve these certifications, and even harder to maintain them. We have received accolades and national awards in safety, quality control, and design. We have the creativity to deliver a design-build project. We have the experienced in-house engineering team to back it up. We have PCI I, II & II Certified Production and QC/QA teams to back it up. Our production facility is also PCI, NPCA, Caltrans and ISNetworld certified. And we have the leadership to back it up with our key managers having an average of over 20 years of precast experience.”

“As StructureCast prepares to find increased success in an ever-expanding market, it will remain focused on delivering a personalized customer experience and cultivating a team with extensive industry knowledge.”

StructureCast’s esteem within the industry comes not only from its ability to deliver, but also from its robust industry associations. The company is a forerunner in developing and championing UHPC (ultra-high-performance concrete) and is one of a select-few precast companies approved to manufacture products with Ductal® in California.

Although there are other companies offering prefabricated modular buildings in California, StructureCast takes a unique approach. Not only does it offer a turnkey, functional, and affordable end result building, but a completely customizable and customer-focused experience. “Our difference is that we engage from the beginning with design-build, with the owner, with the municipality, and general contractor to deliver a more project specific outcome,” says Anna. “We perform like a GC for the production of our units. We partner with the best suppliers for outfitting. We do our own installations. Our method allows for customer engagement from conceptualization to completion.” StructureCast is a regional licensee for Easi-Set, a nationally established company, whose offerings include sustainable, modular buildings. The modular building concept has been an important contributor to StructureCast’s success by bolstering its operations, diversifying its offerings with a shorter life cycle product, and preparing for market fluctuations by underpinning sustainability for the company.

Preparation has also paved the way for some unique collaborations for StructureCast. Most notably is the company’s commitment to community engagement by forming significant relationships with universities and other institutions of higher learning, for instance engaging with architects and engineers at the University of California Irvine (UCI) and the University of Southern California (USC). “We are always looking to the future. Because we perform design-build, we want to be at the leading edge of precast concrete construction and what is happening in design, and construction, and building. And the best place to cultivate that is to collaborate with universities, to understand and contribute to what they are putting into their curriculum. We want to know how we can partner with them to connect with graduate students. We want to learn from them and also to share our knowledge so that they come out of school excited to design with precast concrete,” says Anna. For StructureCast this looks like symposiums, lectures, and speaking engagements, participation in competitions and projects, and even coursework development.

Another way that StructureCast stays prepared to take on the challenges of an evolving precast market is through industry associations. Recognizing PCI West (a chapter of Precast/Prestressed Concrete Institute) as the gold standard of precast concrete certification, StructureCast wanted to be part of the membership. “We realized once we began to scale up and grow our business and product lines, that we wanted to adhere to the highest standards of our industry. We looked at the criteria and the requirements of PCI. We knew that we wanted to achieve that. We wanted to inspire confidence from our clients. Through continuous improvement, we wanted to be among the best in the precast industry and to be qualified to do our best work for our customers,” says Anna.

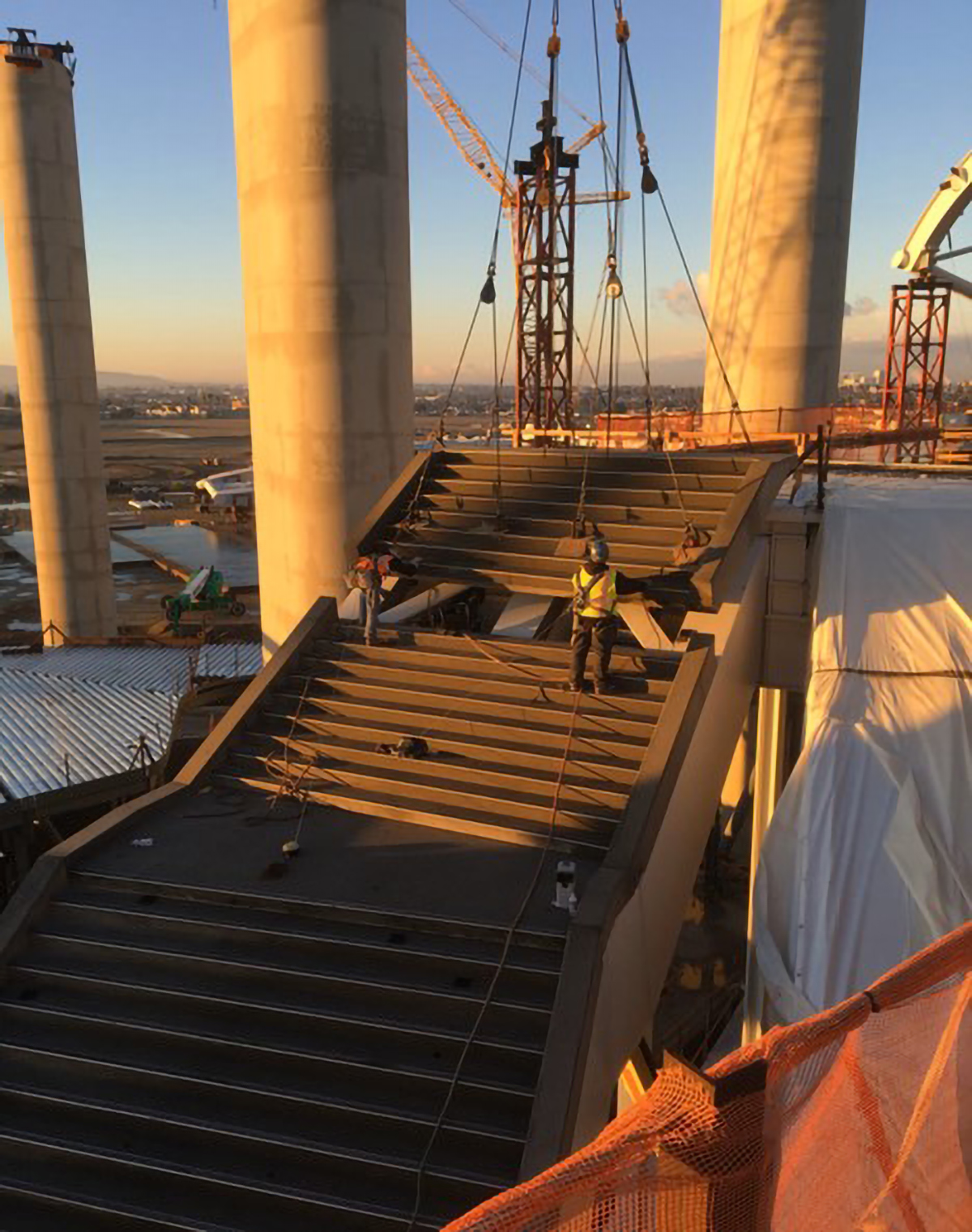

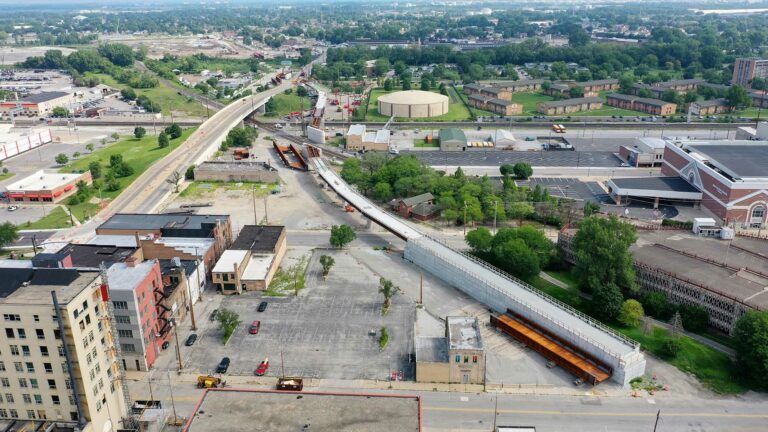

Its unrivaled acclaim as a high-caliber provider of both precast products and service has presented the opportunity to work on some very high-profile projects like the concrete stair systems of the SoFi Stadium in Inglewood, but also some more classified projects that are military and nuclear/energy-focused, and forward-thinking projects with Tesla.

As StructureCast prepares to find increased success in an ever-expanding market, it will remain focused on delivering a personalized customer experience and cultivating a team with extensive industry knowledge. Taking leadership roles in PCI and NPCA (The National Precast Concrete Association), as well as having been awarded Quality Awards by both organizations, fosters the opportunity for StructureCast to both learn more and influence the precast industry. StructureCast is also very committed to earmarking a large portion of its annual operating budget for training. “We believe in this investment because it not only gives our team satisfaction in what they do, it also helps us grow the wealth of information we can bring to each project and to each customer.”

And because it operates primarily in California, StructureCast emphasizes an environmental component to the growth plan. “We are always trying to be part of the cutting edge of what is happening environmentally in our industry. Through training and innovation, we can bring an insight and a thoughtfulness to our customers, so we are all ready to meet emerging regulations and best practices,” says Anna.

As Brent and Anna Dezember lead StructureCast’s next steps for future success, their strategy is total scale up. The team will remain focused on its current service areas and product lines, with a continued emphasis on a custom, design build experience. This means leveraging an ever-growing knowledge and experience base and encouraging customers to envision bigger and better outcomes. StructureCast is a company that sees no limits and has a team prepared to meet every opportunity that comes its way –

On Time, On Plan and On Budget.