The team at Refractory Service Inc., or RSI, as it is often called, know materials in a way many of its competitors don’t. Headquartered in the heart of the Midwest, RSI provides refractory castable, brick, mortar, ceramic fiber, and installation services to meet industry needs across the United States. What sets this company apart is its goal to prioritize quality at all costs. With a wealth of knowledge and a breadth of expertise across a variety of industries including aluminum and steel foundries to die-casting, manufacturing, steel, ethanol and Petro-chem, Refractory Service Inc. is the go-to for those looking to get their job done right, first time.

RSI’s beginnings can be traced back to the visionary minds of Jon Webbers and Milton Stall. Webbers and Stall were the company’s forward-thinking founders who, after noticing a gap in the market, decided to do something about it. Webbers and Stall, armed with valuable experience working at another prominent refractory company, launched the company in 1957. It was the perfect time: Milwaukee was the epicenter of heavy industry and small engine production.

They identified a real opportunity to become the go-to refractory for large-scale companies headquartered in the area, including Briggs and Stratton, Kohler, Tecumseh, Harley Davidson. Alongside this, the location was hugely busy with many foundries producing iron, grey iron, steel, and aluminum.

The largest hurdle in those early days was getting a foot in the door in an extremely competitive refractory industry. Thankfully, the two had significant sales experience and leveraged their backgrounds to establish a robust client base quickly. Over time, their work spoke for themselves, and they gained well-deserved credibility. This led to the company building on a foundation of trust and quality.

Those same values have contributed to RSI’s continued success. However, this growth and success also stems from a workforce comprised of expert craftspeople and highly trained engineers with decades-long experience in the refractory industry. Thanks to this deep industry knowledge and understanding, the company’s design and construction departments can provide custom and turnkey solutions for all unique refractory needs —no matter the complexity. That, coupled with facilities centrally located in Jackson, Wisconsin, and St Paul, Minnesota, means RSI can quickly dispatch and serve clients anywhere across the country.

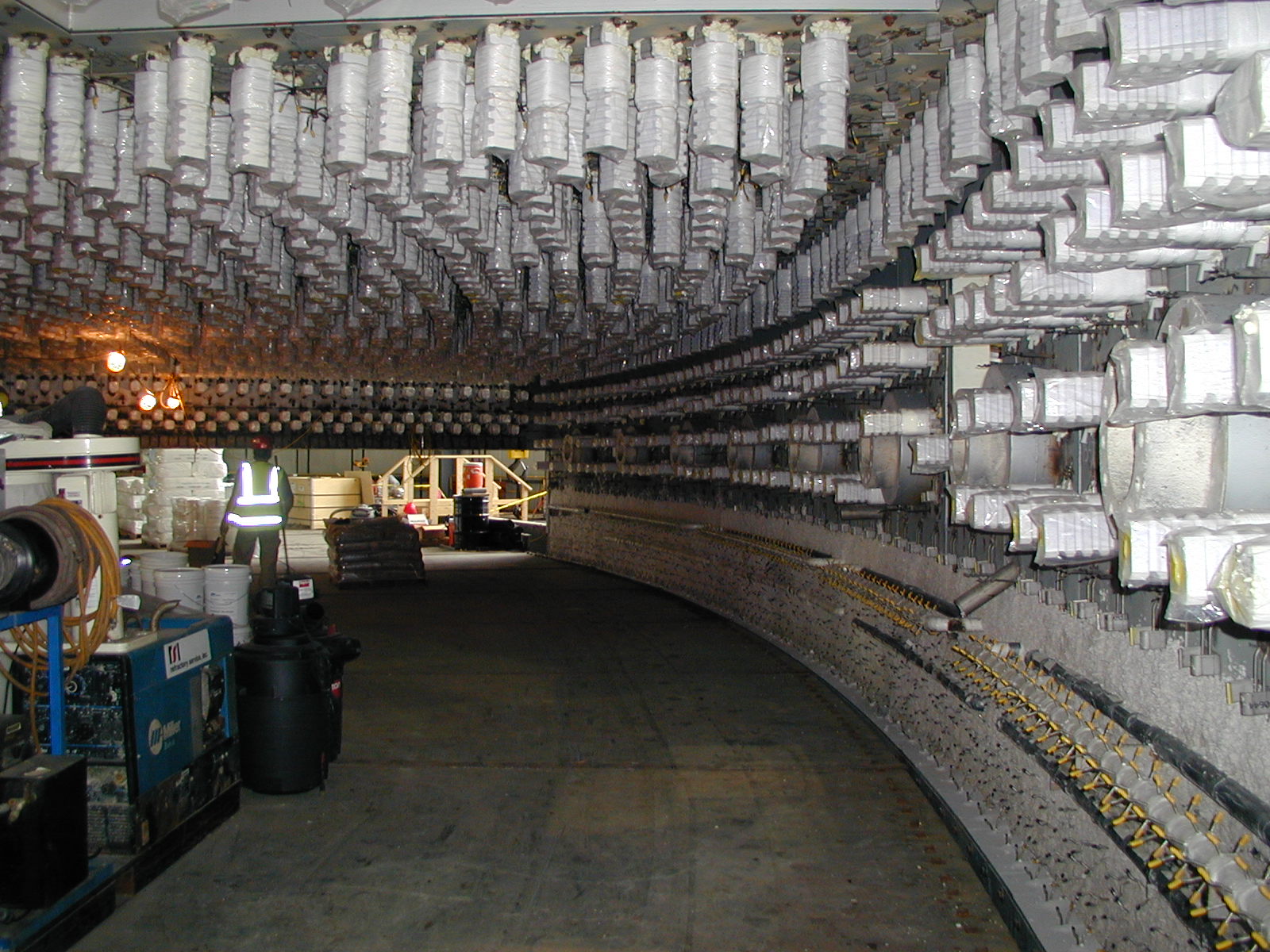

Whether you need new custom equipment design and fabrication, or your existing equipment requires service, materials, or support, RSI is a one-stop solution to ensure you get the materials and expertise you need. From lining a kiln, to creating a simple patch, to a complete tear-out and rebuild, RSI is ready to ensure that its clients have the refractory bricks, linings, ceramic fiber, and media materials required to produce a successful construction project.

“RSI is a one-stop solution to ensure you get the materials and expertise you need.”

Beyond materials, RSI offers unparalleled support and expertise to its clients. Communication is always clear and concise while budgets and timelines are established and adhered to. RSI’s trained support team uses the latest technology, including thermal imaging, to ensure equipment is working as efficiently, safely, and reliably as possible. It even specializes in preventative maintenance, planning, and assessment to help its client’s equipment perform long after its installation date.

With technical expertise and engineering capabilities, along with an integrated manufacturing facility, RSI is proud to design and build for customers’ specific and custom refractory-related needs. RSI offers technical solutions for top load melters, aluminum holding furnaces (electric or gas), zinc diecast furnaces, rotating specialized furnaces, ladles, heat treat furnaces, launder systems, filter furnaces, forging furnaces, and many others.

In addition to manufacturing and supplying a wide range of refractory products, RSI provides a value-add by offering complete installation services for furnaces, boilers, and other industrial projects. Experienced and trained installation professionals marry technical know-how with professionalism to support all stages of the project’s lifecycle, from design to delivery.

Counter to the tenets of client-service, RSI’s ‘ideal customer’ is an unhappy one. In fact, the company is accustomed to swooping in and saving the day, often being called on to take over an ongoing project or fix past work of competitors, providing installations and services that enable better performance.

“It’s not unusual for us to have a client approach us who may have spent $100,000 on refractory work and it’s failed because it was put in wrong and they need us to go in and repair the job for another $100,000,” says Mark, adding, “We are not the cheapest provider you can find…but we always deliver a quality service.”

For Refractory Service Inc., a union contractor, the average employee has 20 or more years of tenure. The team sticks around, motivated by excellence and innovation —the thread that runs through the organization. “We have made it a point to hire management that come from a refractory manufacturing background so that the wealth of experience runs deep,” says Refractory Service’s Director of Sales and Marketing, Mark Sullivan. Sullivan himself has been associated with the company dating back to 1997 and underwent intense training, shadowing his predecessor over a year before taking the job on solo, where he has been for the past 5 years.

One way the company is living its corporate culture is by championing innovation through its work to solve issues relating to expected refractory service timelines for ethanol. In fact, RSI and its expert teams even developed a novel material solution, that simply did not exist a mere five years ago. The solution involves modifying ceramic fiber-based refractory products to create a proprietary, highly energy-efficient system that effective eliminates catastrophic lining failure in high-vibration environments. Coupled with a proprietary coating, which eliminates alkali-induced shrinkage, the system has been 100% foolproof since its inception nearly 3 years ago. The solution is working well, Sullivan says. In fact, RSI recently installed a new lining for an ethanol client that had a long history of vibrational related failures and lining shrinkage, but has now been enjoying 29 months and counting of maintenance free performance.

“This absolutely changed the game with regards to performance of pollution control equipment in the ethanol industry. It’s one of our crowning achievements,” says Sullivan.

In addition to its pioneering work in the ethanol industry, RSI is committed to doing its part to help the planet. The question RSI continues to ask itself is simple: what can we do to put less carbon in the atmosphere and remain on the forefront of leveraging renewable power sources, like wind and solar energy, in future projects? For now, the company is focusing on providing a level of efficiency to reduce power and natural gas usage by 15 – 20% and Sullivan says sustainability will remain a key focus moving forward, guided by the innovation and commitment to quality that has forged RSI’s path over the last 60 years.

Looking for top-notch refractory services? Submit a project request via the company’s contact form.